Building a Better Drawer

At TrippNT we improve today for a better tomorrow. Often those are small improvements but sometimes they are HUGE.

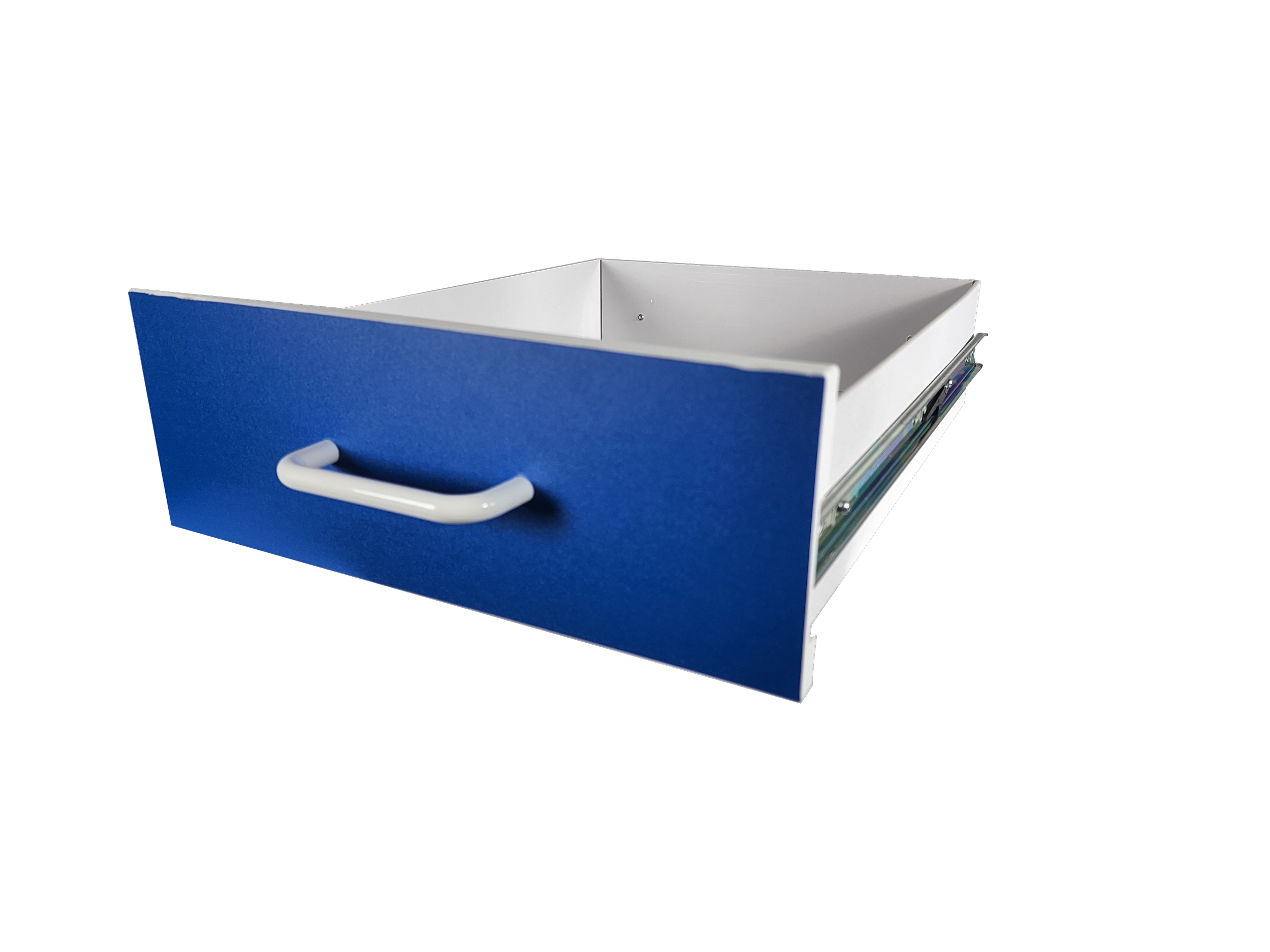

Most carts have drawers. And drawers have traditionally been the biggest challenge in building a cart because they were made from Acrylonitrile Butadiene Styrene (ABS) and required a heating jig. The heating jig softens the drawer at its crease - so that a Cart Line Specialist can bend up the sides and back of the drawers. However, heating jigs can be inconsistent. This resulted in the occasional burned corner (waste) or longer takt time (waste again).

Then, one of our engineers, Jay, had the idea to do away with heat all together. He designed a drawer made from Aluminum Composite Panel (ACP) that does not require heat for construction. The change resulted in a stronger, better drawer that is easier to build and has fewer defects.

The new drawer will eventually become universal to all our cart models - further reducing tact time as all drawer construction will be standardized.

At TrippNT, we are committed to identifying and eliminating waste so that our customers get the maximum value in their products.